What’s the best way to keep our screens clean? The first, and obvious answer, is to keep our hands themselves free of grime. But there may be another option: self-cleaning coatings created by materials scientists.

Recently, Anish Tuteja, a materials researcher at the University of Michigan, developed a clear, smooth coating that repels all liquids and can be applied to any surface. (The research was published in the journal ACS Applied Materials & Interfaces.) There are other repellent coatings, of course, but their abilities are limited. Take, for instance, a Teflon pan. “If you put a drop of water on it, it beads up, but if you put cooking oil, it’ll spread,” says Tuteja. “That’s what happens on most surfaces.” The material his team developed is far more versatile and, he hopes, will be available in the next couple of years.

The Verge spoke to Tuteja about the repellent, how his team develops new materials, and what’s next for self-cleaning materials.

This interview has been lightly edited for clarity.

As a scientist, you work on “surface science.” What is surface science and what are its potential applications?

My group at the University of Michigan works primarily on different types of surfaces that either attract or repel different liquids. It’s a unique surface that doesn’t quite exist in nature but has a lot of fundamental applications.

In terms of repelling liquids, look at almost any surface around you and you can find an application from screen displays to tables and chairs and carpets. There’s a lot of use for self-cleaning materials and stain-resistant surfaces.

Another area is for heat transport, to enhance condensation on surfaces. That’s relevant for all power plants and nuclear plants in the world. [Editor’s note: Power plants generate steam that turns a turbine to make electricity. The turbine is condensed into water and the process starts again, but the condensers can be inefficient.] It’s useful for refrigeration, too — anywhere there’s a phase change or anything that comes from a vapor to a liquid, there’s condensation, this would be relevant and help save energy.

You said these surfaces don’t exist in nature, but what would be the closest naturally occurring material that has these properties?

A lot of the work in the repellant area has been on textured surfaces. These are rough surfaces that trap pockets of air under different liquids. The lotus leaf is the common example: water droplets will come in and bounce out.

That repels water, but not other materials like oil and alcohol. Take your non-stick Teflon pan, for example. If you put a drop of water on it, it beads up, but if you put cooking oil, it’ll spread. That’s what happens on most surfaces. There aren’t smooth surfaces that repel everything.

And your coating is a smooth surface that can repel liquids. You call it “omniphobic.” What does that mean, exactly?

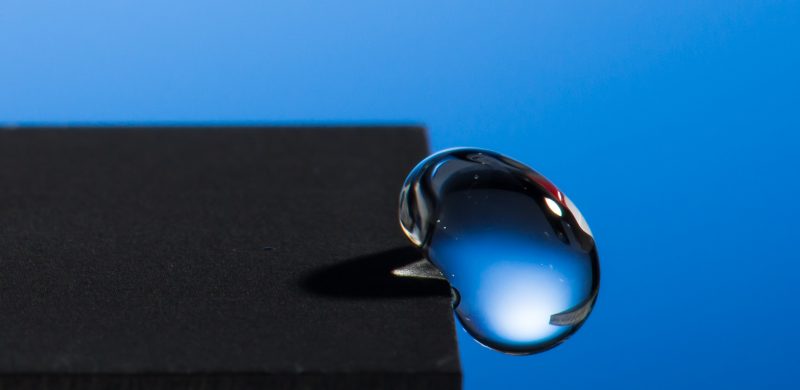

The surface resists wetting. Our definition of “omniphobic” coating means that liquid that will not spread. So different liquids like water, oils, and alcohol will not spread on the surface. Plus, the droplets of liquid can just slide off the surface very rapidly, which makes them very easy to clean. So, if you have a camera lens with the coating, you can tilt the surface and any water or oil on it will just slide off.

I was interested in how you came up with the idea. Instead of mixing together materials, it involved a lot of calculations to see what might work together, right?

Absolutely. To make a repellent, you typically take a material called a filler and a polymer binder and mix them together. The polymer binder provides the durability and the filler provides these repellent properties. So, you might think that if you take the most durable filler and the most durable polymer and mix them together, that would lead to the most durable surface.

That’s not the case. What’s important is how well these components mix and interact, which we call “miscibility.” Instead of mixing and matching, we did our own calculations of the properties of many substances to find the best range. We mathematically came up with formulations that might work well together, and that means we’re not limited to just one formulation. It allows us to look at different polymers and different fillers and find out which ones are likely to have similar properties. It allows us to predict which might be the best substances.

What does the coating feel like? And how long would it last? Say I use the coating on my iPhone — when would I need to reapply it?

It’s thin and it’s hard. It’s based on urethane, which is a rubbery material, so it kind of feels like a stiff rubber coating. Regarding how long it would last, it depends on exact formulation, but we’re hoping for something on the order of a year.

What about getting these to market? When will that happen?

We’re actively working on getting surfaces like these to market. We’re working with a start-up, Hygratek, which I co-founded, to get this to market within the next one to two years.

The major challenge we’re trying to address is the durability of the coating, and to get it to have a good feel. And, of course, you want to make sure that the cost is not too high. We’re trying to figure out an optimal formulation, and not just one, to see which ones would be most cost-competitive.

Do we know for a fact that this won’t have any health effects?

We are testing. The molecule used in this paper contains fluorine, and there’s a lot of data that we have on how it’s not toxic. But there are ongoing things that we need to figure out. And this molecule is still only available in relatively small quantities, which is why we’re also looking at other formulations that are nontoxic and based on more commercially available materials, different combinations of polymers.

What else are you working on? What else is being developed in surface science?

We’re also working on omniphobic coatings that repel or kill microbes, and materials that are ice-phobic. In these, ice doesn’t adhere, so it would be very useful for airplane landing strips and power lines and wind turbines. We’re also making dust-resistant surfaces.

In surfaces that attract water, we’re creating surfaces that will attract water but repel oil. Nothing like that exists in nature, where you can get oil to bead up but water to spread on the surface. These membranes could be used for cleaning up oil spills, for example.

Original article extract taken from theverge.com